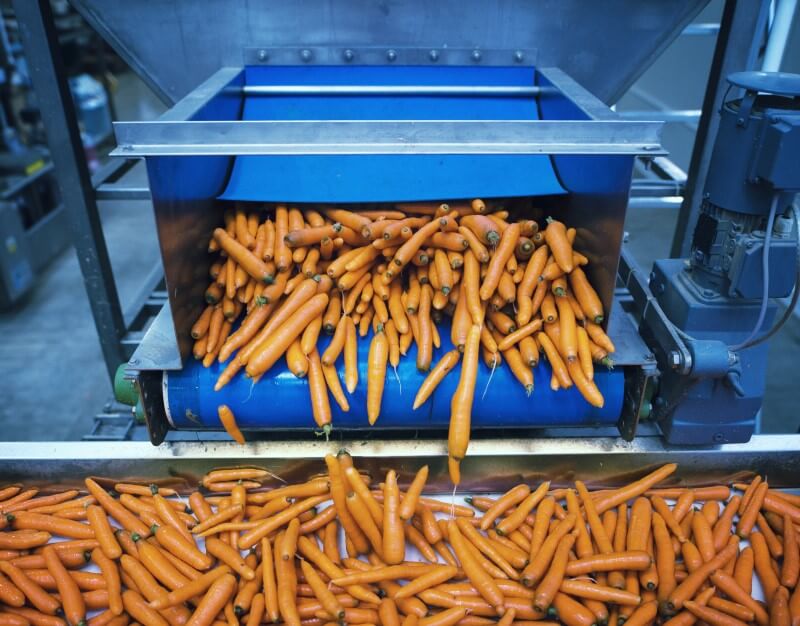

Creating a safe and hygienic Food Processing Environment

When it comes to food manufacturing process, safety and hygiene are non-negotiable aspects. Business owners ensure that the food they provide for their beloved family is safe, nutritious and free from any contaminants. Achieving such a food processing operation and standard demand meticulous attention, especially designing in commercial kitchen and processing environment.

This article explores unique design considerations involving in creating safe and hygienic food processing environment for manufacturing food in commercial kitchen.

-

Stainless Steel Materials

Stainless steel is the gold standard when it comes to materials for food processing equipment and surfaces. Its smooth, non-porous surface resists bacterial growth, making it easy to clean and sanitize. In commercial food manufacturing facilities, stainless steel is used for everything from countertops and sinks to mixing bowls and processing machinery. Its durability and resistance to corrosion ensure that it can withstand the rigors of daily use and frequent cleaning, maintaining a hygienic environment for food production. Thus reducing labor work and financial stain on the business owners.

-

Easy-to-Clean Surfaces

In addition to stainless steel, commercial kitchens must be outfitted with surfaces that are easy to clean and sanitize. This includes walls, floors, and equipment surfaces. Smooth, seamless surfaces minimize the risk of bacteria buildup and make it easier to remove food residues and spills. Non-absorbent materials such as ceramic tile, epoxy flooring, and high-density polyethylene are commonly used in commercial food processing environments for their ease of cleaning and resistance to moisture and chemicals. Keeping the environment free from chemicals and strain means that best practice of cleanliness is applied in the commercial setting and testament of their best food manufacturing as well.

-

Sanitary Equipment Features

When selecting equipment for commercial food manufacturing, it’s essential to choose models with sanitary design features. This includes equipment with rounded corners, sloped surfaces, and minimal crevices where food particles and bacteria can accumulate. Sanitary equipment is also designed for easy disassembly and cleaning, with quick-release mechanisms and removable parts that allow for thorough sanitation. Look for equipment that meets industry standards for sanitation, such as those set by the Food and Drug Administration (FDA) or the European Hygienic Engineering and Design Group (EHEDG).

The practice of keeping separate sanitary equipment also indicate that the commercial business is observing recycling and greener practice in the food production. the environment and waste is tackled at root cause perspective.

-

Separation of Raw and Ready-to-Eat Areas

To prevent cross-contamination, commercial food manufacturing facilities should have separate areas for handling raw ingredients and processing finished products. This includes dedicated storage areas, preparation zones, and processing lines for raw materials and cooked or ready-to-eat products. Physical barriers, such as walls or partitions, can further segregate these areas and prevent the transfer of contaminants between them. Additionally, employees should follow strict protocols for personal hygiene and sanitation to minimize the risk of contamination during food handling and processing.

Prioritizing Pet Food Safety Through Design

Creating a safe and hygienic food processing environment is essential for commercial food manufacturers to ensure the safety and quality of their products. By incorporating design considerations such as stainless steel materials, easy-to-clean surfaces, sanitary equipment features, and separation of raw and ready-to-eat areas, manufacturers can minimize the risk of contamination and produce food products that meet the highest standards of safety and hygiene. With a commitment to food safety and quality, manufacturers can earn the trust and confidence of customers.