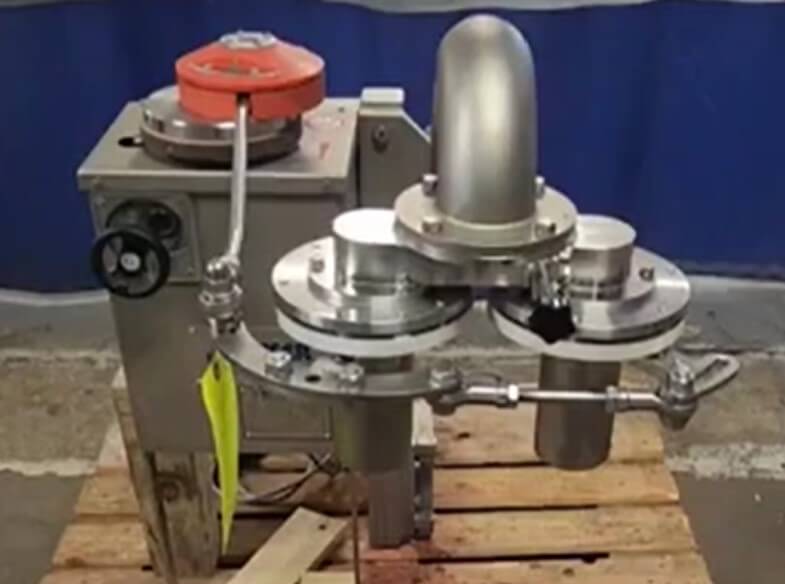

Vemag 821 Diaphragm Meatball Former

The Vemag 821 Diaphragm Meatball Former is a specialized piece of commercial equipment designed for the efficient and consistent production of meatballs. This machine is particularly used for high volume food productions such as meat processing plants and commercial kitchens.

The Vemag 821 Diaphragm Meatball Former is a dynamic automate machine for forming meatballs with uniformity in size, shape and weight. Here’s the detailed process of how the machine functions and processes uniform meatballs.

Process of making Meatball with Vemag 821 Diaphragm

The Vemag 821 operates through a series of mechanical processes that work together to form meatballs quickly and efficiently. Here’s a step by step overview of how the machine works.

1: The process begins by feeding the ground meat mixture into the hopper of the Vemag 821. The hopper is designed to accommodate large quantities of meat, making it ideal for continuous operation in a high volume setting.

2: The mixture is conveyed from the hopper into the machine via a vacuum stuffer secured by brackets. This vacuum stuffer moves the mixtures evenly into the double headed pump for the diaphragm portion. The vacuum pipe can work separately from the hopper or meat conveyor.

3: Once the meat mixture is pumped, it is transferred to a two-headed diaphragm system for portion and forming of meatballs. The diaphragm is made of durable food grade material and is responsible for portioning the mixture into precise amounts.

4: In the diaphragm system, the portioning is highly adjustable. It allows operators to set the size and weight of the meatballs. This feature is crucial for meeting specific product requirements for maintaining consistency across the large batches.

5: After adjustment to the size and weight of the meatballs, the machine molds shape and forms perfect spheres. The diaphragm system ensures that the pressure applied during the forming is consistent, preventing any deformities in the meatballs.

6: Once the meatballs are formed, they are gently cut by the blade attached to the diaphragm system. They are gently dispensed onto a conveyor belt or directly into a container for further processing.

7: The machine minimizes the risk of damage to the meatball during dispensing through maintaining their shape and appearance. This is done with the help of a speed control wheel.

Benefits of Vemag 821 in Commercial Food Plant

The machine is crucial in commercial settings where consistency is key to both product quality and customer satisfaction. The machine is used in a versatile environment and various meat types such as chicken, pork, lamb and even vegan substance. Some of the major benefits of the Vemag 821 Diaphragm Meatball are as follows.

- The Vemag 821 is significant for making large quantities of meatball production in a short amount of time.

- The precision of the diaphragm system ensures that every meatball is uniform.

- This machine can handle a wide range of meat mixtures including different textures and ingredients, making it more adaptable to various production needs.

- The cost effectiveness side of this machine resolves commercial kitchen and food processors cost and problems.

Buy your Vemag 821 Meatball Former at M&M Equipment

The Vemag 821 Diaphragm Meatball Former is an essential piece of equipment for any commercial operation that requires high volume consistent meatball production. Its advanced portioning system combined with its efficient operation and ease of maintenance makes it a valuable investment for food production businesses.

At M&M Equipment, the Vemag 821 equipment is available for large scale food manufacturing plants at optimal performance and reliability. So, meet the demands of modern food production and get your Vemag 821 at an affordable price at M&M Equipment.